Quality Assurance & Testing

Search

Quality Assurance begins with purchasing and Scaffold Depot has high expectations of our suppliers.

We know that our supplier relationships directly influences our ability to provide a quality product and professional service to our customers.

It is for this reason that Scaffold Depot made a solid decision from early on to acknowledge the importance of developing strong working relationships with a select few manufacturers of products not manufactured in-house.

These long-term relationships have been maintained because of the direct influence this has on our ability to built trust in quality products and provide professional service to our customer.

Our long-term supplier relationships have enabled us to develop a clearly defined list of quality criteria for the products to be supplied to Scaffold Depot. It is this continuity of relationships that will allow for the continuous exchange of information to contribute to an ever improved product and service quality. Scaffold Depot is compliant with the various international standards applicable to our customer requirements, and conducts all of it's Product Testing using industry approved testing Agencies.

Verification

Verification

Even if great care is taken to ensure products are ordered correctly and that only approved vendors are used; never can you assume that a product is correct. It's incredibly important that any defects are caught early before materials are used in manufacturing or shipped to customers.

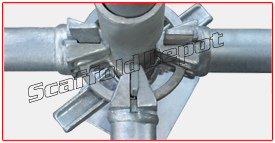

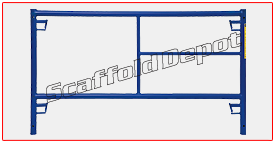

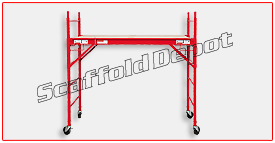

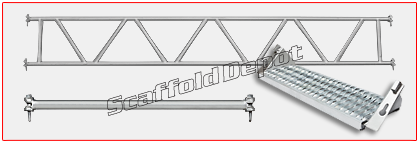

Material Receiving Inspection reports have been implemented and are required to be completed whenever a new shipment is received at Scaffold Depot. They range from deck components, extrusions, clamps, ring system, access frames, worm pins, and so on. The inspection reports include all basic measurements that need to be recorded, and any ares that need visually inspected for each component. These inspections will be covered in great detail as we continue through the presentation.

Production and Traceability

Production QA lies in conducting appropriate in-process inspections to ensure that components are manufactured within set parameters, and that diligence is exercised at all stages of the assembly process. Working with the manufacturing management and supervisors, Scaffold Depot identified areas where inspections are required and implemented reports that are to be completed at set intervals, as well as final inspections.

After materials have been ordered and received, and manufacturing is complete, 3rd party testing is required to ensure that components meet all applicable specifications and industry standards.

3rd party testing enables Scaffold Depot to hold suppliers accountable for the products that we order, as well as confirm for our customers that our products also meet all requirements. 3rd party testing can also be considered part of the verification process. The only difference being that every component received by Scaffold Depot is not subject to testing. Scaffold Depot will be implementing parameters at which components need to be sent for 3rd party testing as the standard operating procedures for each product are developed. These parameters will be based on new products, proven product performance.