Manufacturing Process

Search

Manufacturing

The importance of being able to manufacture new products in-house allows us to respond in a professional and expedient manner to inquiries made by our customers

In order to continue growth of Scaffold Depot we recognize the importance of developing new working relationships with manufactures & the development of new products to be manufactured in-house by Scaffold Depot.

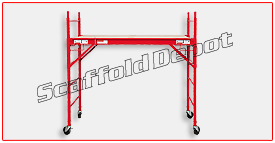

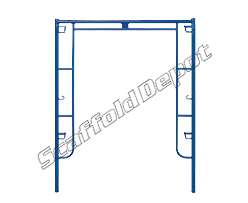

The importance of being able to manufacture new products in-house allows us to respond in a professional and expedient manner to inquiries made by our customers. An example would be the flexibility of being able to manufacture on short notice custom sizes and design of products such as RhinoBuilt Work Platforms. Often industrial demands for scaffold products have short timelines that are not conducive to purchasing from offshore suppliers. Scaffold Depot with it's manufacturing capabilities has the ability to manufacture and ship products on short notice across Canada and the United States.

Industry Competitive Costs & Availability

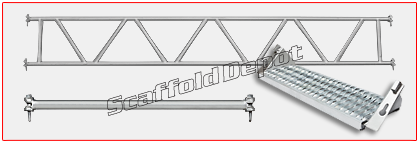

As a manufacturer of a number of scaffold products, Scaffold Depot has been able to reduce the final cost of these products by manufacturing them in-house. Buying locally reduces shipping timelines and freight costs. Offshore freight pricing may be increased due to the rise in the price of oil.

Automation has allowed Scaffold Depot to remove a portion of the Labor costs incurred when building scaffolding components. This has made Scaffold Depot manufactured products costs more inline with offshore manufactures. Short delivery timelines prevent downtime on large construction sites where this labor downtime can be costly.

Strong Network of Supplier Relationships

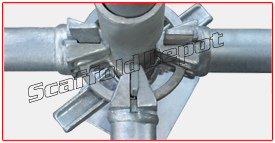

Consistency is a major factor in the Quality Assurance Process. Scaffold Depot acknowledges the importance of developing strong working relationships with a select few manufacturers of products we could not manufacture in-house ourselves. Long-term supplier relationships enable a partnership to develop that clearly defines the quality aspects of the products to be supplied to scaffold depot.

The continuity of our relationships allows for the exchange of information to improve product and service quality in addition to amicable settlement of any disputes that may arise. Working in partnership, joint efforts improve quality, reduce costs, and increases market share for both parties.

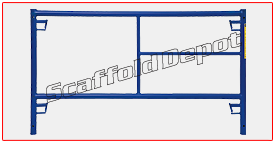

Scaffold Depot has expaned it's production to include:

• Steel Planks

• Toeboards

• Steel Top Decks

This ability to manufacture provides the equipment and man-power to work on projects such as the gap-filler and collapsible toeboard initiated

International Standard Compliance

Scaffold Depot is compliant with the various international standards applicable to our customer requirements. Scaffold Depot conducts all it's product testing using industry approved testing agencies.